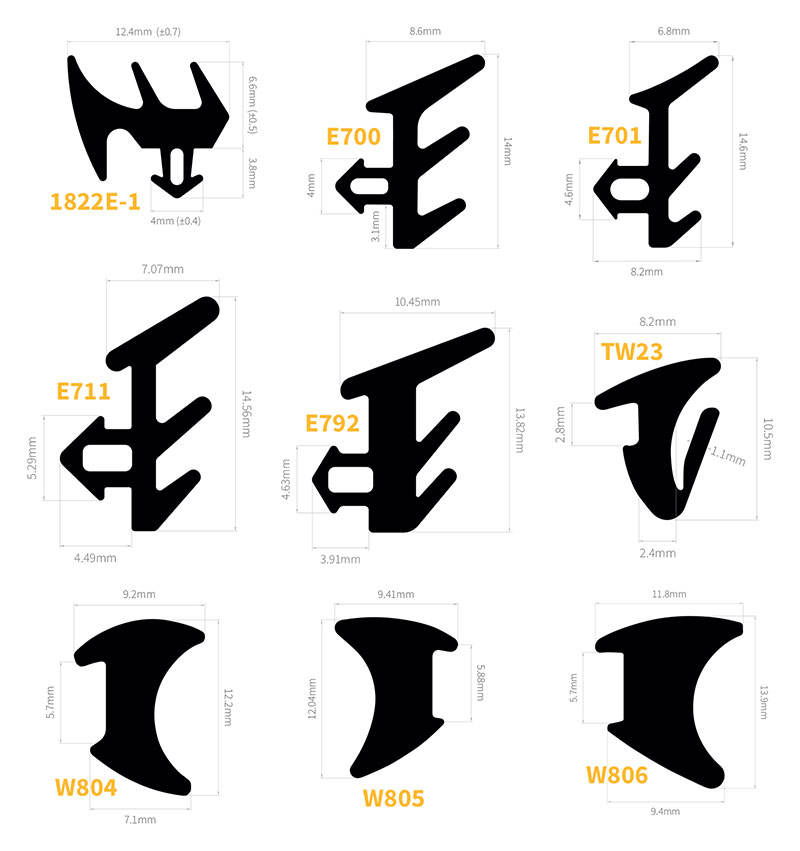

Sample Pack of Wedge & 'E' Rubber Gasket for Windows and Doors

Want the right gasket - test for absolute certainty!

Samples of rubber wedge and E gasket, for testing in window and door profile before larger purchase. Frequently paired, with 'E' Gaskets used on one side of the frame, and the Wedge Gasket on the reverse. They create a watertight and draught-proof seal between a window or door frame, and it's double-glazed unit or infill panel.

Replacing gaskets is quick and easy and requires minimal tools, and doing so can stop water ingress, eliminate draughts and noise, improve energy efficiency, safety and security.

Features & Benefits

- Seals between double-glazed unit and frame

- Stops water ingress, draughts and noise

- Durable core strengthens and resists overstretch

- Long-lasting UV stable and weather resistant

- Replacing inefficient seals reduces energy bills

- Fit easily without special tools or adhesive

Explanation of Wedge and 'E' Gaskets

As their name suggests, Wedge gaskets are wedge shaped, so they can simply push into place between frame and double-glazed unit. They feature a rib that hooks onto the frame to keep it in place. Wedge gaskets are designed for easy fitting, and also easy removal, should a unit need to be changed, or 'E' gaskets replaced on the other side.

'E' Gaskets get their name from their profile, which can resemble the letter E, and are also referred to as Fir Tree gaskets because they resemble the downward slopping branches of a fir tree. A mushroom extrusion that runs along these gaskets is pushed tightly into a groove in the profile. Then under compression against the double-glazed unit, the branches of the fir tree create multiple seals.

How to get the right gasket

Knowing the name of your window or door profile may help identify the gasket needed, as may be comparing the following drawings to the profile of your existing gasket. Perhaps the most trusted method is to purchase a sample pack, and testing the samples in your actual gasket groove.

DID YOU KNOW?These are made from a Thermoplastic Elastomers (TPE) material, a blend of plastic and elastic polymer. So they're durable, thermally efficient, with a core of polypropelene (PP), or PVC nitrile, to resist overstretch and expansion.